THE TEARDOWN

The engine was running fine, until it wasn't. Follow along as the guys dig in to find what happened, and what can be reused.

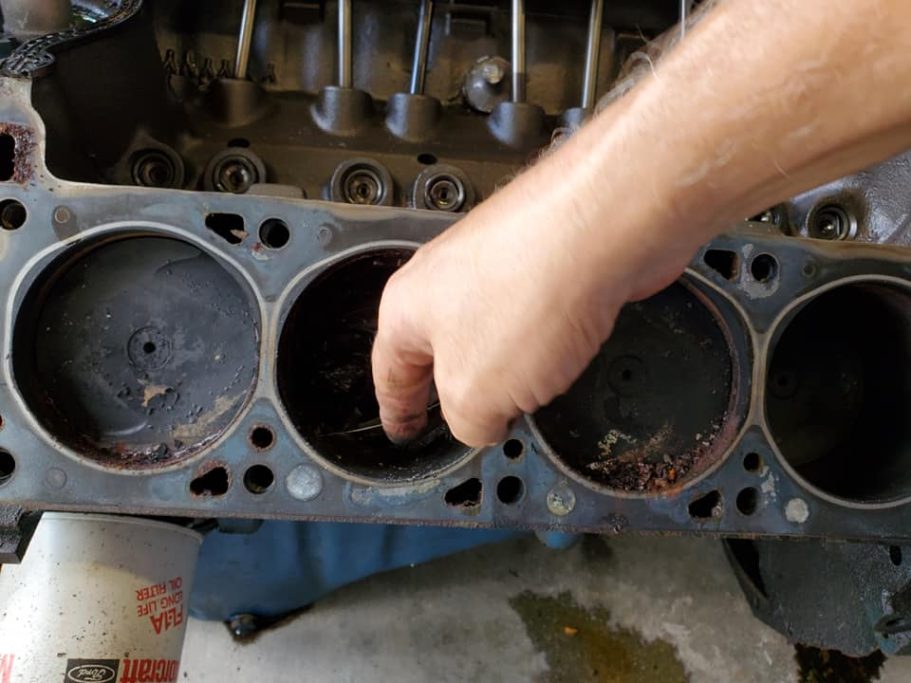

WHERE DID THAT VALVE GO?

Valves control the intake of air and fuel into the engine, and the exhaust of combustion gases into the atmosphere. Most valves of this era are three pieces of steel, welded together. This works fine in millions of cars until consumers begin reaching for more torque and horsepower. These power gains are often achieved by upgrading the valvetrain components, which frequently includes stiffer springs. These springs exert more tensile force on the valve stem, occasionally leading to the valve and stem separating at one of the welded joints.

THAT'S NOT SUPPOSED TO BE THERE...

We believe this failure to be due a dropped valve that, after billions of cycles, gave way at one of the factory joints. This valve was continually dropping out of the head and hitting the top of the piston (accounting for the cyclical 'knock' we were hearing) and the stroke of the piston would shove the separated valve back into the head. This allowed the engine to continue operating in a crippled state until, during one of the stroke cycles, the separated valve dropped completely out of the head. This time there was too much material and not enough space. This led to the piston being eccentrically loaded, blowing out the side of the cylinder wall, and seizing the engine.

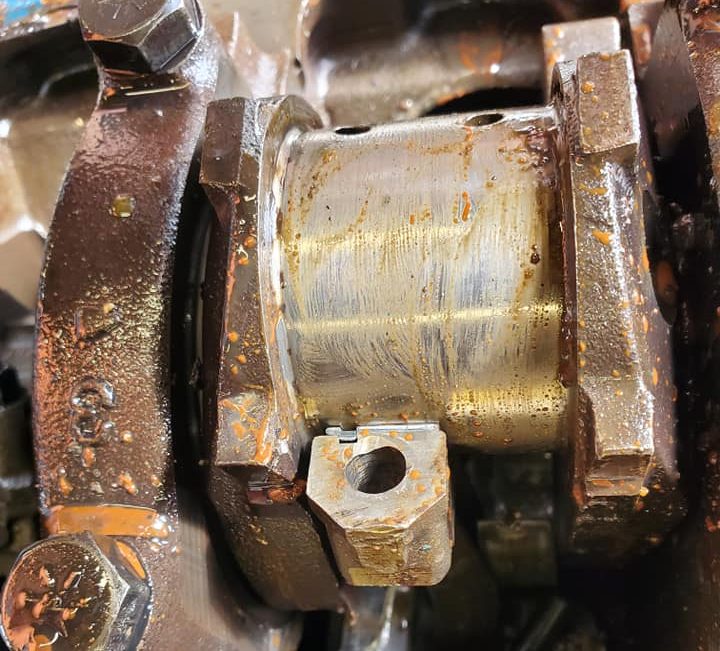

ROD JOURNAL

Surprisingly, the factory rod cap held up very well. The rods and caps were secured with ARP High Strength Rod Bolts. The crankshaft, and affected rod MAY be okay, but must not be reused without being closely checked by a competent machinist. My bet is that the sudden force snapped the neck of the rod.

Gallery

A few photos of getting the car stripped down to a starting point.

© Copyright 2023. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.